The electrical and electronic (E/E) architecture of vehicles has changed dramatically as cars are becoming a computer on wheels. Consumers expect advanced safety features and demand rich in-car tech – all driving the rapid increase in automotive electrification and connectivity.

Electronic Control Units (ECUs)

At the heart of E/E architectures is a series of electronic control systems (ECUs), each an embedded system that controls one or more vehicle systems. Typical ECUs include engine, drivetrain or transmission control; HVAC control; infotainment and telematics. In modern vehicles, all systems related to driver assistance and automated driving, from sensors to actuators, are controlled by ECUs. These ECUs are interconnected via vehicle communication networks.

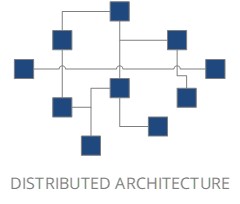

The history of automotive ECUs dates back to when electronics first made its appearance in vehicles. In the early days, each control unit was limited to a certain function such as engine control, ABS system, or HVAC. As more features are added to vehicles, the number of ECUs increased – up to 200 in some high-end cars. ECUs were usually interconnected by means of low-speed CAN, LIN or similar busses. This vehicle architecture is known as distributed architecture. Distributed ECUs are typically simple, with few requirements for precision timing. Data links were slow. A crystal or even an unprecise RC oscillator were sufficient to clock ECUs.

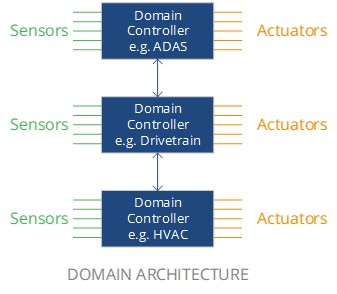

Over time as more advanced features were designed into automobiles, the number of ECUs has grown. This growing number of ECUs represented a high cost and significant wiring challenge. However, at the same time, processor technology improved to the point that one controller could manage several functions – in essence enabling the consolidation of ECUs within a domain. Hence, the domain architecture was born.

Domain Architecture

In a domain architecture, each ECU rules over a specific domain. Each domain controller is connected to the sensors and actuators which are related to its functional area. Typical vehicle architectures feature the following domain controllers:

- Connectivity / telematics

- Automated driving and driver assistance systems (AD/ADAS)

- Powertrain / vehicle dynamics

- Body and comfort

- In-vehicle experience / infotainment

The transition to domain architecture has a significant impact on timing.

- The architecture relies on higher-speed interfaces. This is achieved by means of Ethernet, FPDLink, GMSL and similar interfaces. High-speed interfaces need low jitter clocks to function correctly. Excessive jitter increases the bit error rate (BER) on the bus. In many cases, high clock accuracy and stability over temperature (in other words, low ppm) is critical.

- ECU complexity has increased, therefore more clocks are needed. Some domain controllers, in particular AD/ADAS, are built on several processors (e.g., main SoC and a vision coprocessor), all interconnected by PCI-Express. PCI-Express Gen 4, widely used in automotive systems in 2022, requires a 100 MHz differential clock with <500 fs jitter (integrated over 12kHz to 20 MHz). The low-jitter SiT9396 oscillator is ideal for generating this clock.

- Integrated clock generators streamline the bill-of-materials while optimizing other design parameters such as board space, power consumption, or EMI. Please contact SiTime for more information on clock generators.

- Functional safety is an integral part of today's automotive systems. ASIL D is mandatory with most domain controllers. Clocks play a significant role in supporting Functional Safety requirements.

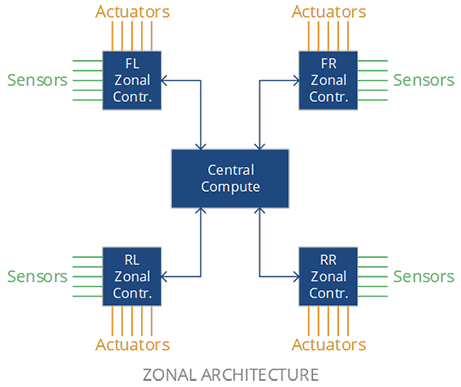

Going Further with Zonal Architecture

As efficient and elegant as the domain architecture is, the proposed zonal architecture represents a way to further optimize automotive electronic systems. Here, sensors and actuators are connected to a local zonal controller or gateway, regardless of their function. Future E/E architectures will consist of a few controllers connected to a very powerful centralized computer. This architecture has the potential to further reduce wiring and optimize compute power. Zonal controllers can also offload the central computer by performing pre-processing tasks.

Zonal architecture relies heavily on high-speed interfaces. The requirements it poses on timing will be even more stringent than with domain architecture – demanding even lower jitter clocks, higher timing accuracy, and better stability over temperature.

How SiTime's MEMS Timing Solutions Can Help

SiTime MEMS timing solutions provide the requisite performance for today’s E/E architecture and the zone-oriented architecture of tomorrow. Compared to quartz-based timing components, SiTime devices offer several advantages that are particularly important for automotive applications.

- Better frequency accuracy, 10x lower aging, and excellent stability over temperature – down to ±20 ppm (XO devices) over -40 to +125°C and ±0.1 ppm (TCXO devices) over -40 to +105°C.

- Up to 50x better reliability. Apart from reducing the amount of field failures, better reliability translates into a lower FIT rate. This provides better hardware safety metrics in an FMEDA, the quantitative analysis required as part of a functional safety assessment.

- 100x better resilience to shock, vibration and electromagnetic interference, due to the smaller size and lower mass of MEMS resonators compared to crystals. When not causing a permanent damage to the crystal, shock and vibration can induce jitter in a crystal oscillator that can be detrimental to the bit error rate of a high-speed link.

................................................................

Featured automotive MEMS oscillators

- Single-ended oscillators: SiT8924 and SiT9025 with spread spectrum

- Differential oscillators: SiT9396 and SiT9397

- Super-TCXOs: SiT5386 and SiT5387