Precision control in automation — whether in medical robotics, factory automation, textile manufacturing, printing, or autonomous vehicles — has experienced explosive growth over the past decade. Irrespective of the type of motor and application, achieving a high level of precision of multiple variables such as torque, position, speed, and angle have necessitated the use of oscillators instead of crystals to achieve the required precision in these applications.

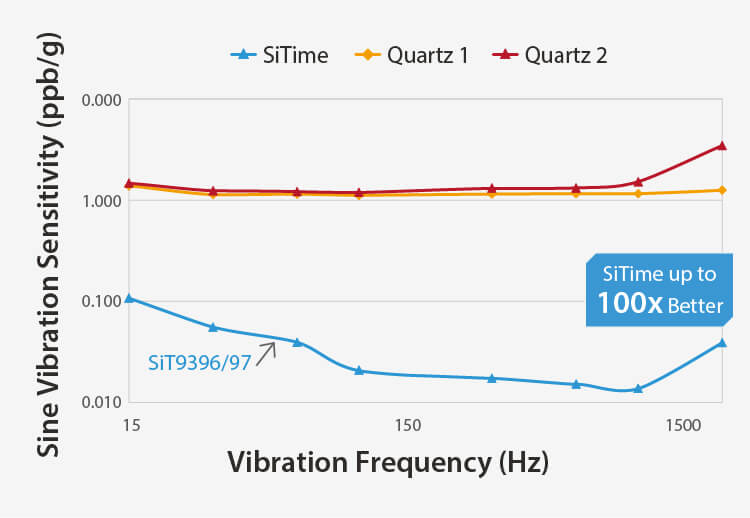

Encoders have traditionally used crystals in the measurement of speed, torque, and position. To control multiple variables in high precision motors, drivers must continuously receive input from the encoders and instantly take corrective action through feedback to the motors. As motor manufacturers strive to improve precision with faster response, they have begun to implement drivers alongside each motor. This subjects drivers to higher vibration and shock, requiring robust components that can meet design considerations.

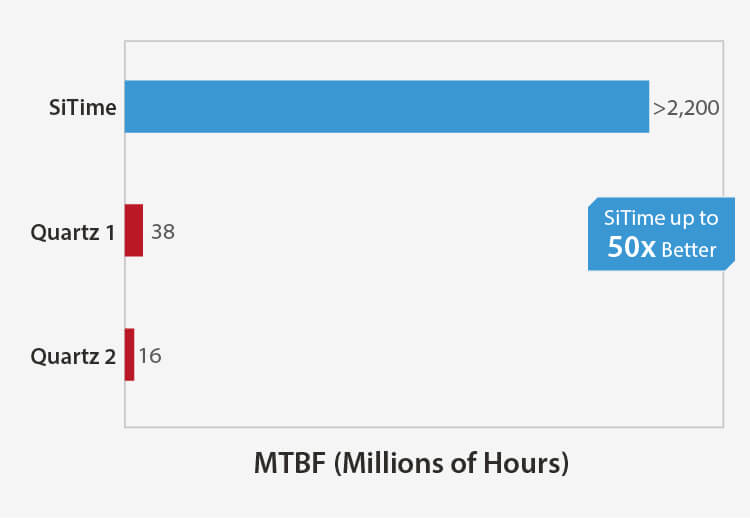

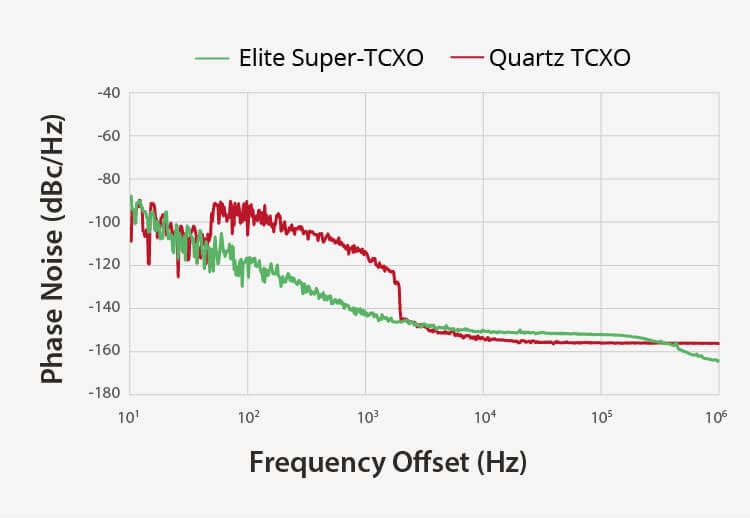

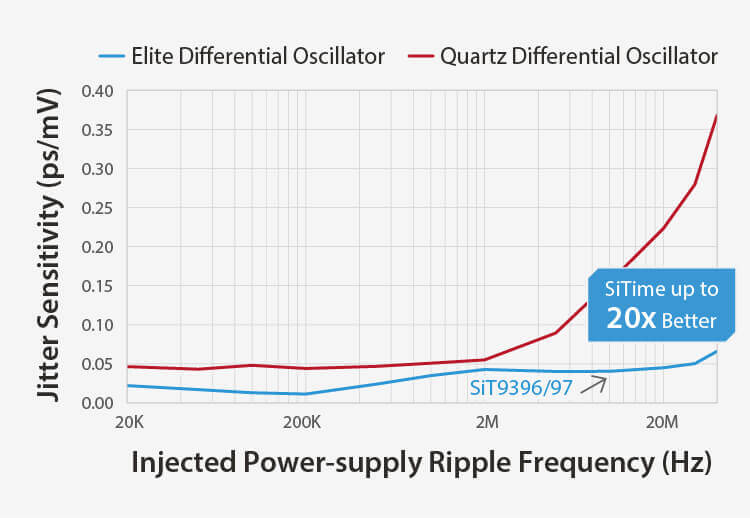

SiTime oscillators are robust and can withstand the continuous vibration and shock from motors and the environments in which they are used. Besides enabling good SNR (signal-to-noise ratio), SiTime oscillators offer strong protection against moisture permeability and the ingress of chemical and gas particulates. In addition, they offer the following benefits:

- Wide operating temperature

- Temperature stability

- Small size