Automotive LiDAR

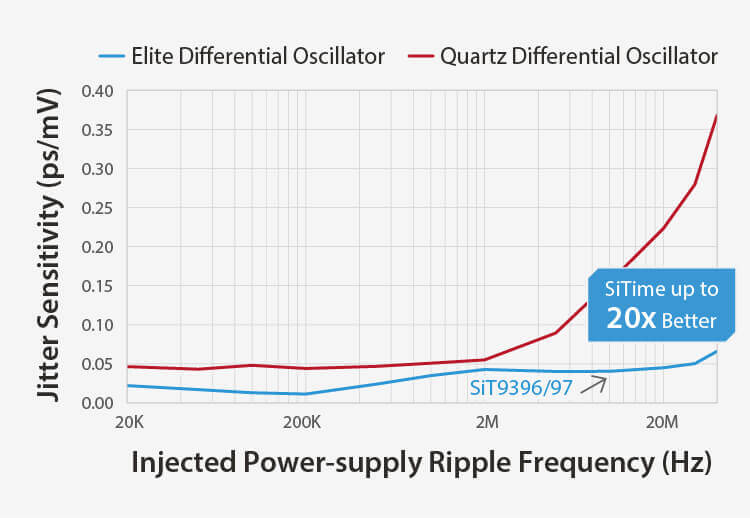

Several measurement methods exist: Time of flight (ToF), frequency modulated continuous wave, or time digital conversion (TDC). Precision timing plays a big role to ensure accuracy of the system. The low jitter of the SiT9396 and SiT9397 make those devices ideal to clock the analog part of LiDAR applications.

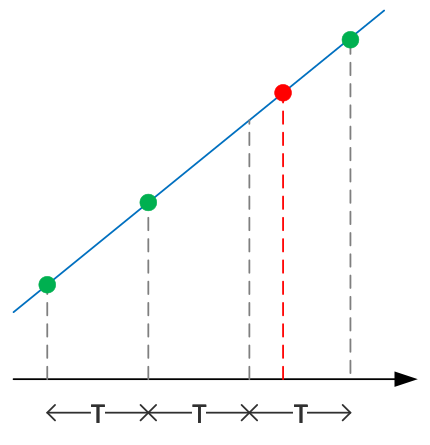

When an ADC is used, jitter causes quantization errors. When excessive jitter is present on a clock, in other words when a clock edge comes too early or too late, an ADC samples the incoming signal at the wrong moment. Incorrect values in the data stream can significantly hamper the functionality of a system.

The excellent dynamic performance of SiTime silicon MEMS oscillators facilitate SOTIF (safety of the intended functionality) compliance of the system. The MEMS oscillators ensure that clocks remain within spec over its entire lifetime, regardless of environmental changes.

- Temperature range -40°C to +125°C

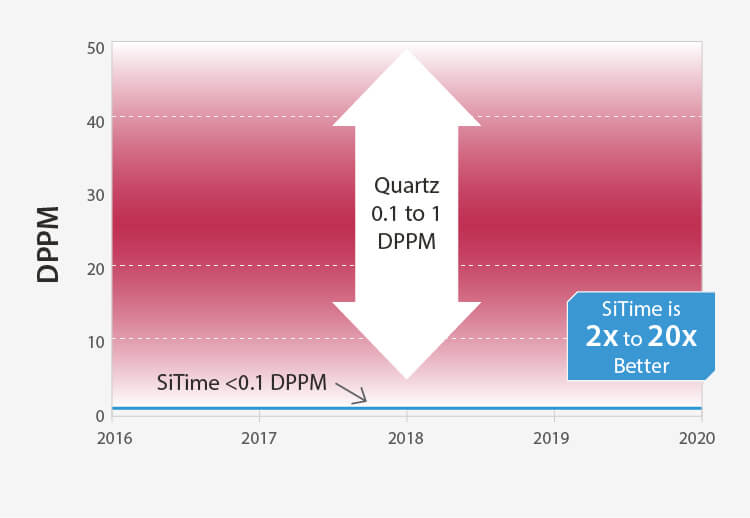

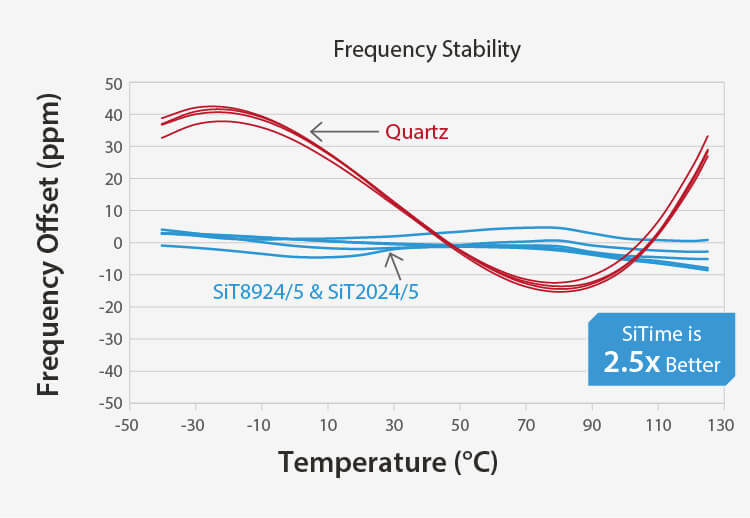

- Well controlled frequency stability: < ±30 ppm over the full temperature range, including 10 years aging (SiT939x), down to ±0.1 ppm for TCXO (SiT538x)

- Excellent frequency response to rapid temperature changes dF /dT, down to < ±3.5 ppb/°C (SiT538x)

SiTime Advantages

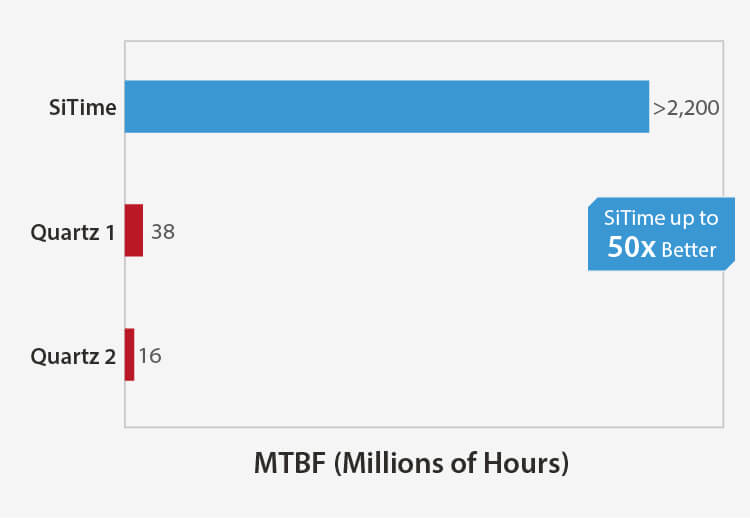

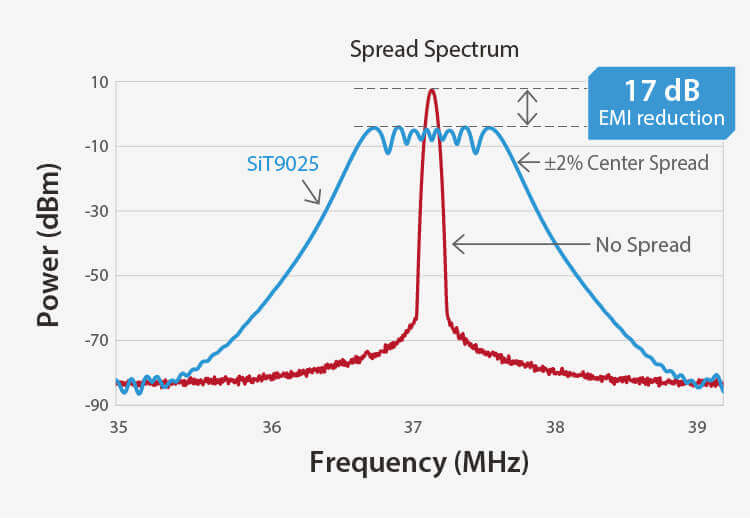

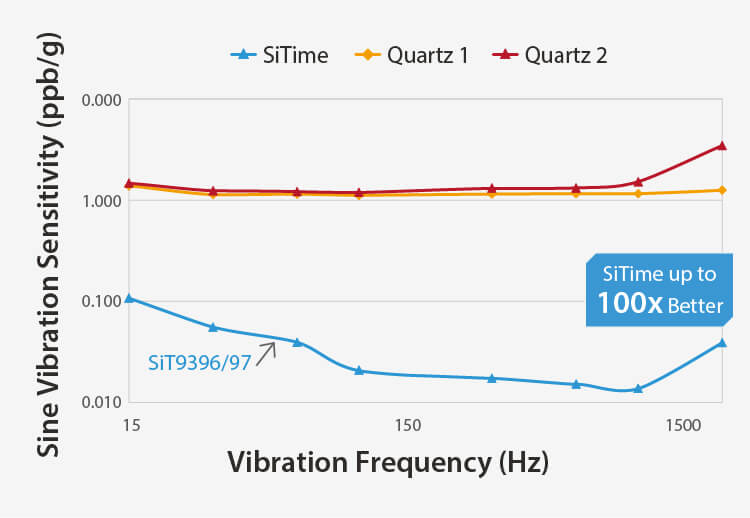

All SiTime devices offer the following advantages over quartz crystals, which are particularly important for automotive applications:

- 50x better reliability. Apart from reducing the amount of field failures, the better reliability translates into a lower FIT rate. This provides better hardware safety metrics in an FMEDA, the quantitative analysis required as part of a functional safety assessment.

- 100x better resilience to shock, vibration and electromagnetic interference, due to the smaller size (0.4 x 0.4 mm) and lower mass of MEMS resonators compared to crystals.

- MEMS oscillators typically have a faster startup time than crystal oscillators.