What is a Battery Management System (BMS)?

A battery management system (BMS) is an electronic system that manages a rechargeable battery cell or battery pack and monitors its health. The primary function of a BMS to:

- Authenticate

- Protect the battery from operating outside its safe operating zone

- Monitor the voltage, current, and temp during operation

- Manage the SoC (State of Charge) and other variables during charging

- Control its environment (temp, pressure)

- Report these parameters to the central monitoring unit

Regardless of battery type (pouch or prismatic) or chemistry, a BMS is necessary to avoid catastrophic failure.

BMSs are offered in multiple topologies and sizes depending on use case.

- Centralized: Single controller for multiple batteries. This is economical but causes increased weight and cost due to wiring

- Distributed: A BMS for each cell. This is most expensive but easiest to install

- Modular: A few controllers for a finite number of cells

BMS configurations are highly dependent on application and are different for mobile and stand-alone applications.

- A BMS for EVs, industrial/military drones is a subsystem and tightly integrated to charging system, thermal and the communication sub-systems

- A BMS for an uninterrupted power supply (UPS) or Industrial tools is standalone

Applications

- Electric vehicles

- E-Bikes, E-Scooters

- Industrial / military drones

- Industrial tools (mowers, blowers)

- Uninterrupted power supply (UPS)

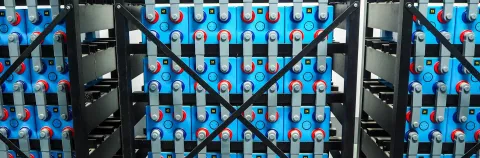

- Energy storage system (ESS)

- Autonomous vehicles for warehouse robotics, mining, underwater, etc.)