MEMS Timing Solutions for Smart Mirrors

| Devices | Key Features | Key Values |

|---|---|---|

|

Single-ended Oscillator

SiT8924 1 to 110 MHz

|

|

|

|

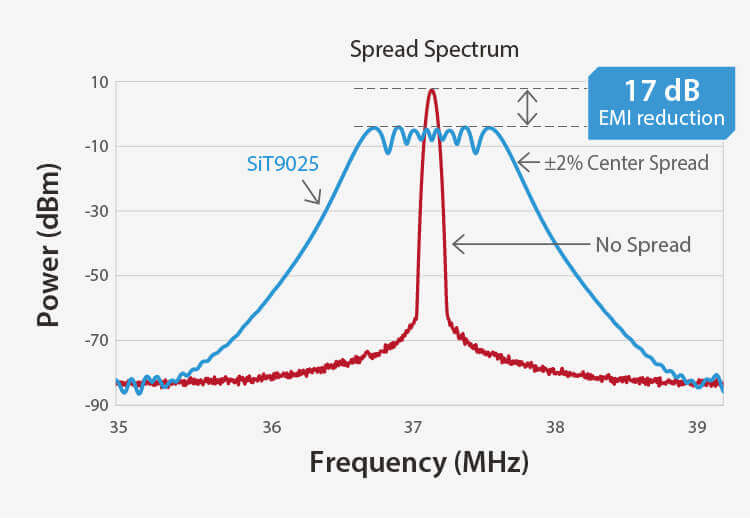

Single-ended Oscillator

SiT9025 1 to 110 MHz

|

|

|

|

Differential Oscillators

SiT9396 1 to 220 MHz

SiT9397 220 to 920 MHz

|

|

|

|

Super-TCXOs

SiT5386 1 to 60 MHz

SiT5387 60 to 220 MHz

|

|

|

1 12 kHz to 20 MHz integration range