How to Solve Costly Design Problems with EMI Reduction

Regulatory bodies set limitations on RF emissions emanating from industrial and consumer products. Meeting these standards can be challenging and costly, especially with increasing processor speeds and data rates in today’s electronic systems. The challenge of combating EMI is compounded as products shrink and are designed to consume less power.

Traditional EMI containment techniques such as shielding become more costly and impractical as products get smaller. Because mechanical solutions are expensive and space consuming, the use of spread spectrum modulation has become a popular means to reduce EMI. Designers can use a spread spectrum clock generator IC and crystal. However, this combination can also be too bulky, difficult to implement, and inflexible for many applications.

Designers now have a new tool for reducing EMI

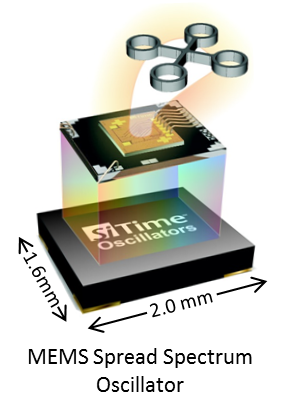

With the introduction of MEMS technology and a programmable architecture, ultra-small spread spectrum oscillators (SSXOs) provide an extremely effective and easy-to-use low-power solution for reducing EMI. The new SiT9005 SSXO combines a MEMS resonator and advanced analog circuitry into a tiny 2.0 mm x 1.6 mm DFN package. This MEMS SSXO has a 95% smaller footprint and 70% lower height than the smallest quartz-based SSXO.

Typical supply current is 4 mA at 1.8V and only 0.2 µA in standby mode, with a startup time of just 5 ms. The SiT9005 frequency ranges from 1 MHz up to 141 MHz, with stability over temp as low as ±20 ppm. MEMS and analog technology make this device extremely robust, with 10x better AC coupling noise injection immunity and 30x better shock/vibration resistance compared to quartz. In addition, it has the best cycle-to-cycle period jitter at <15 ps (picoseconds), ideal for clocking high-speed chips.

The device’s small-form-factor, low power, and flexible EMI reduction options make the SiT9005 an ideal solution for products prone to radiating unwanted RF energy. Examples include IP cameras, car camera modules, industrial motors, tablets, flat panels, and printers.

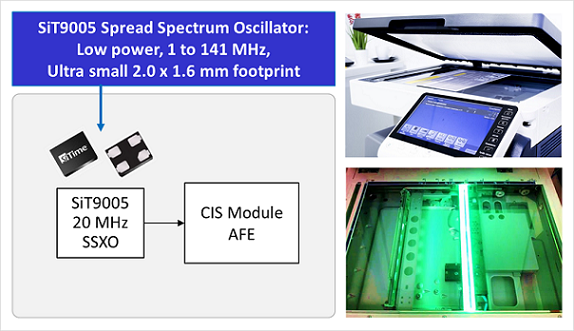

Small size and low power are two key requirements for CIS MFPs

Let’s look at contact image sensor (CIS) type multifunction printers (MFPs). CIS-type printers are significantly lower power and smaller than charged coupled device (CCD) MFPs. The sensor scanning module in CIS MFPs must be small and lightweight as it travels under the platen glass to scan documents. Since glass doesn’t filter RF energy, EMI is allowed to propagate—making an emissions-reduction solution like the SiT9005 SSXO a perfect fit.

Fast and flexible options ensure compliance

In addition to the small footprint and low power, the field programmable SiT9005 has a range of flexible options to ensure EMI compliance, a pivotal milestone for any electronic product. Failure to comply, which is discovered late in the product development cycle after a prototype is completely assembled, can result in costly production delays and postpone time to revenue. The SiT9005 SSXO solves that problem by offering two techniques for compliance: spread spectrum clocking and rise/fall time adjustment of the clock signal.

Two methods for reducing EMI with a multitude of options

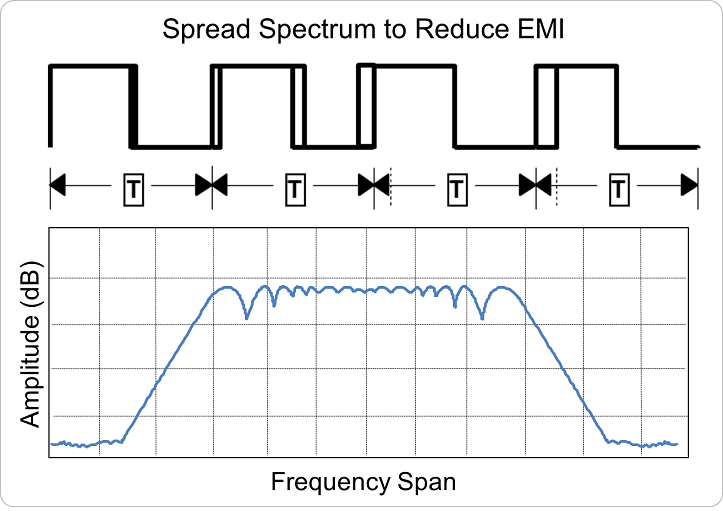

1. 30 total spread spectrum options (2 frequency spread styles and 2 spread profile options):

- Center spread from ±0.125 to ±2.0% with ±0.125% resolution

- Down spread from -0.25% to -4.0% with -0.25% resolution

- Spread profile options: Triangle or Hershey-kiss

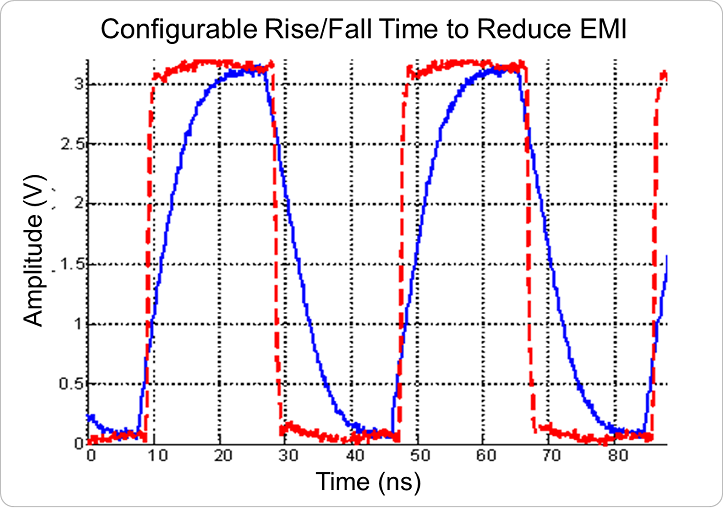

2. 8 FlexEdge™ rise/fall time options:

- Slew rates from 0.25 to 40 ns slew rates

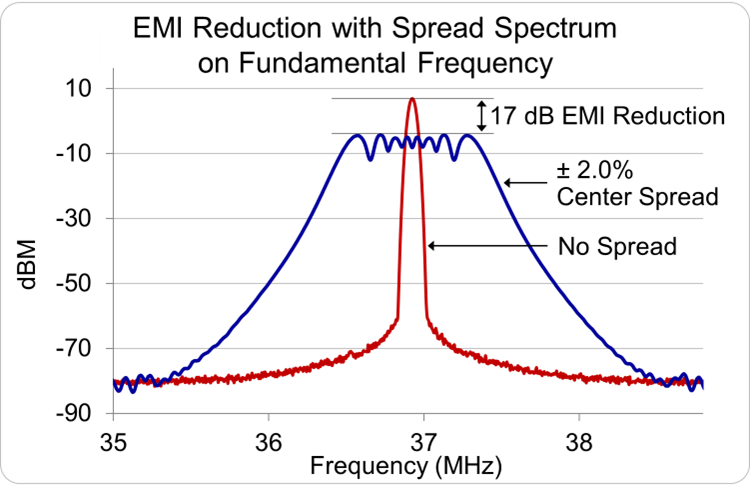

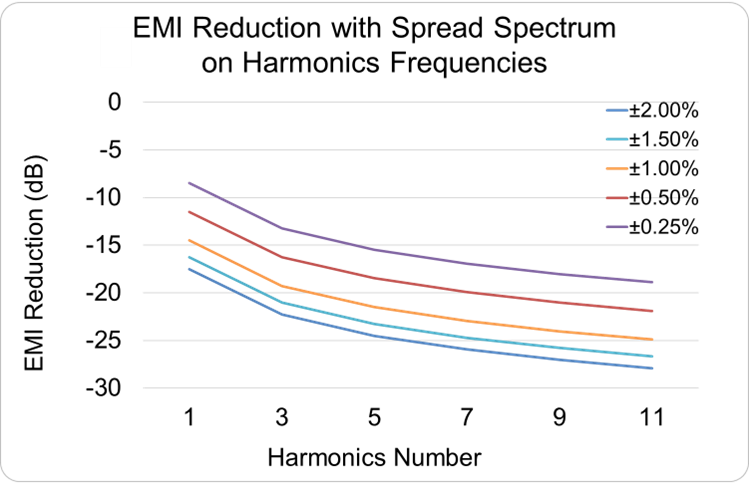

By using spread spectrum modulation alone, EMI can be reduced up to 17 dB on the fundamental frequency and up to 30 dB on harmonic frequencies. What’s more, the SiT9005 is supported by the Time Machine II programmer. This tool enables engineers to instantly adjust both frequency spread and rise/fall time. Designers can experiment in their lab with various settings to find the right configuration for reducing various types of EMI, whether originating from SOC harmonics, clock traces, or data links. Parameters are simply programmed into the non-volatile memory within the SSXO.

Up to 17 dB EMI reduction on carrier frequency and 30 dB on harmonics

An all-silicon MEMS spread-spectrum solution makes the design process extremely low risk and enables the fastest time-to-market. A design can use the SiT9005 without spread spectrum. And if final testing determines spread spectrum is required, the SiT9005 offers a wide range of programmable EMI reduction options in the exact same footprint. If a design uses a quartz XO, the SiT9005 is a quick and easy drop-in replacement without requiring any PCB changes. In addition to the 2.0 x 1.6 mm package, the SiT9005 is available in 2.5 x 2.0 and 3.2 x 2.5 mm packages, all pin-compatible with quartz-based XOs. The result is a very cost effective solution.