Oscillator aging and its importance in precision timing

Frequency stability is the most fundamental performance specification of an oscillator. It represents the deviation of output frequency and is usually expressed in parts per million (ppm) or parts per billion (ppb). A smaller stability number means better performance. A change in frequency can be caused by several conditions such as temperature variation, supply voltage variation, output load variation, and frequency aging. In this blog we focus on aging, the change in oscillator frequency over a certain period of time.

Why is low aging important?

Aging is an important parameter and must be considered during system design in many applications. It is particularly important in systems that require a very stable frequency reference—systems that use precision oscillators such as TCXOs (temperature compensated oscillators) and OCXOs (oven controlled oscillators).

For example, precision oscillators are commonly used in network infrastructure and high-precision measurement equipment to provide a stable backup frequency source. In these applications, an OCXO (and in some cases a TCXO) serves as a local clock in the event of a loss to an external source like GPS. Holdover is the mode of operation when systems temporarily lose connection with the external reference signal and switch to a local source. In this case, the local oscillator, the OCXO or TCXO, must remain extremely stable from hours to days, making aging a critical factor.

Read our Aging in OCXO and TCXO whitepaper for more on frequency aging theory. The discussion starts by diving deeper into the critical factors affecting aging of quartz-based and MEMS-based oscillators. Then a mathematical aging model is used to compare predicted long-term aging performance between MEMS and quartz oscillators with actual aging measurement results. Through an extrapolation of the mathematical aging model, long-term performance predictions are made. Recommendations for future work is presented and an aging compensation algorithm to improve the aging characteristic is proposed.

What causes oscillator aging?

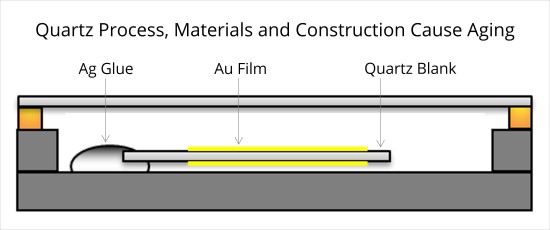

Aging is caused by internal changes within the oscillator. There are two main reasons for aging. One reason is mass loading and the other is stress relief. The root cause of aging in quartz oscillators is primarily due to the manufacturing process, the structural design, and use of various materials in the device. During the manufacturing of quartz resonators, residual stress conditions manifest such as surface crack, polish abrasion during processing, and bonding force between the quartz and the electrode film. The different thermal expansion coefficients of materials cause stress at interface. Additionally, the silicon glue used in quartz oscillators decomposes under heat and causes mass accumulation.

Quartz-based oscillators use materials that make them vulnerable to aging due to contamination and stress relief in the structure.

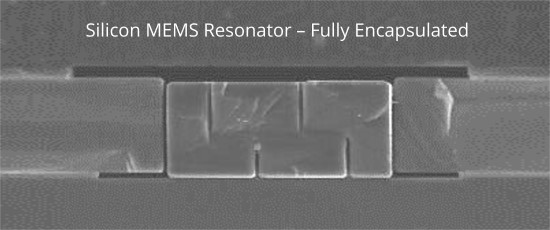

In contrast, MEMS resonators use stable silicon materials with no outgassing properties. The manufacturing process of SiTime silicon MEMS resonators does not introduce contaminates such as those introduced during dicing saw or polish of quartz resonators. SiTime’s proprietary EpiSeal® process forms ultra-clean MEMS resonators that are encapsulated in wafer-scale silicon/polysilicon under a high temperature of more than 1000 °C. The internal residual stress is released by atoms that migrate through a crystal lattice. This creates a clean vacuum environment that cannot be encroached by contaminants. The net effect is resonators with extremely low aging.

Cross section of a SiTime MEMS resonator manufactured using processes and materials that remain clean and stable under long-term operation.

MEMS and quartz aging performance

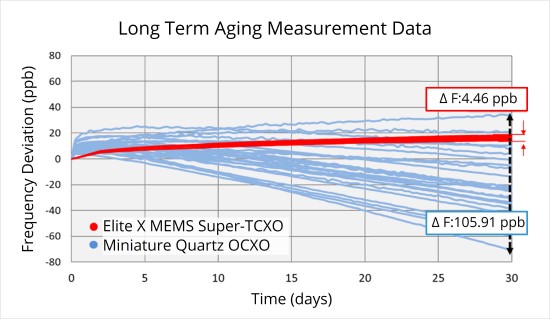

The difference in aging between MEMS and quartz-based oscillators is demonstrated in the plot below. This plot shows 30-day aging measurement data normalized to the first day for a MEMS-based Super-TCXO® (Elite X™ SiT5501) and a quartz-based miniaturized OCXO, both Stratum 3E level oscillators. Both the quartz OCXO and SiT5501 have positive aging at power on. However, over time the negative aging factor of most of the quartz OCXO DUTs becomes greater than the positive aging factor, taking on a negative slope that progressively declines.

Conversely, the SiT5501 quickly becomes stable, and the offset is less than 20 ppb under 30 days of operation. In addition, the aging rate variability between the group of quartz OCXOs is significantly larger than the SiT5501 due to the limitations of the quartz machining process, becoming another contributor to potential failure. Generally, the aging rate specification will be defined after 30 days of operation.

Frequency deviation of MEMS-based SiT5501 Elite X Super-TCXO (red)

vs miniaturized quartz OCXO (blue)

Aging is an inevitable and irreversible process. However, frequency aging deviation can be lowered by leveraging the benefits of the silicon MEMS manufacturing processes that produce encapsulated silicon resonators that cannot be compromised.

……………………………………………

Thanks to Johnson Hsu, Customer Engineer at SiTime, for his contributions to this article.

Related Resources

Products:

Papers:

Timing Essential Learning Hub courses: