The Importance of Robust and Accurate Timing in Seismic Sensor Applications

Seismic sensor-based systems are an essential tool in various industrial applications including infrastructure fault detection, earthquake detection, and geological exploration. These instruments operate in diverse environments, often under harsh conditions. Sensors can be attached to structures, placed underground or used underwater, where they can be subject to movement, shock, rapidly-changing temperatures, and airflow. These seismic sensors can also be deployed in remote locations where the satellite reference is unreliable yet accurate time stamped data is crucial. For this reason, using a robust timing reference within the system is essential to ensure dependable and precise time stamping for extended periods of operation.

Figure 1. Seismic sensing in diverse locations and harsh dynamic environments

Precision oscillators such as TCXOs (temperature compensated oscillators) and OCXOs (oven controlled oscillators), which are designed to provide even better accuracy, are frequently the timing reference of choice for seismic sensor applications. Both types of oscillators can provide ppb-level (parts per billion) stability that is achieved with temperature compensation circuitry. In the case of OCXOs, an added heating element is used to increase consistency of the ambient temperature inside the device. All of this is designed to maintain a high level of stability under rapid temperature transients.

Watch video: MEMS timing solutions for seismic sensors

MEMS Super-TCXO optimized for seismic sensor applications

New MEMS technology has enabled a new generation of Super-TCXOs that provide OCXO-level performance with temperature stability as low as 50 ppb, ultra-low temperature slope, and operating temperatures up to 105°C, all of which are optimized for seismic sensing. These precision Super-TCXOs are based on a novel architecture consisting of a DualMEMS™ die and a mixed-signal CMOS IC with a proprietary temperature compensation scheme and a low-noise frequency synthesizer.

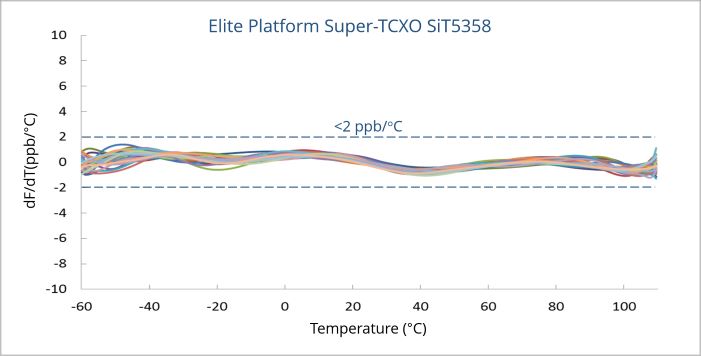

Designed to Eliminate Lag

The two silicon MEMS resonators, comprising the DualMEMS, are co-fabricated together on a single die. One resonator is designed using SiTime’s TempFlat™ MEMS technology to achieve a flat frequency response over temperature. The second resonator is designed to act as an extremely accurate temperature sensor. These two MEMS are thermally coupled because they are located within 100 µm of each other, as physically close as possible. Unlike quartz-based TCXOs, there is virtually no lag between the MEMS resonator and the temperature sensor and compensation circuits. The DualMEMS architecture enables instantaneous response to temperature variations, resulting in an extremely flat frequency-temperature slope as shown in Figure 2.

Figure 2. Elite Platform™ Super-TCXO with ±1 ppb/°C (dF/dT) up to 105°C for accurate time stamping

Shock and Vibration Resistant Super-TCXOs

MEMS-based Super-TCXOs also offer industry leading shock and vibration resistance for extreme environmental robustness—a critical factor for seismic sensors that can be deployed in extreme and uncontrolled environments. Shock and vibrational forces can degrade performance and cause traditional quartz crystal oscillators to fail. Crystal resonators are cantilevered structures that can be very sensitive to mechanical forces. They are prone to increased phase noise and jitter from vibration and frequency spikes from shock. In contrast, MEMS resonators experience less vibration because their mass is 1000 to 3000 lower than quartz resonators. This reduces the force applied to the resonator from vibration-induced acceleration. SiTime MEMS resonators are stiff structures that vibrate in-plane in a bulk mode, a geometry that is inherently vibration-resistant.

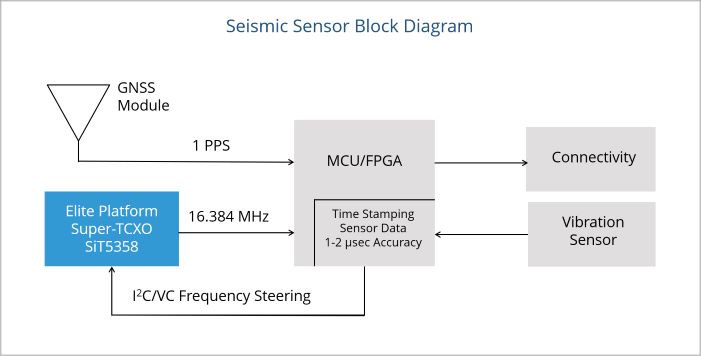

Accurate Timing Independent of GNSS Satellite Reference

Maintaining constant timing accuracy in seismic sensor applications is important. When the GNSS satellite reference is not available, the digitally-controlled Super-TCXO will maintain the timing accuracy needed for operation. With I2C digital control and 5 ppt (parts per trillion) of frequency steering resolution, the TCXO creates a timing loop that synchronizes the output frequency to the last GNSS pulse received, as shown in Figure 3. Time stamping sensor data is accurate within 1 to 2 microseconds. Additionally, using I2C digital control in the timing loop eliminates the noise associated with voltage control.

Figure 3. Frequency Control Loop with Elite Platform™ Super-TCXO I2C Frequency Steering

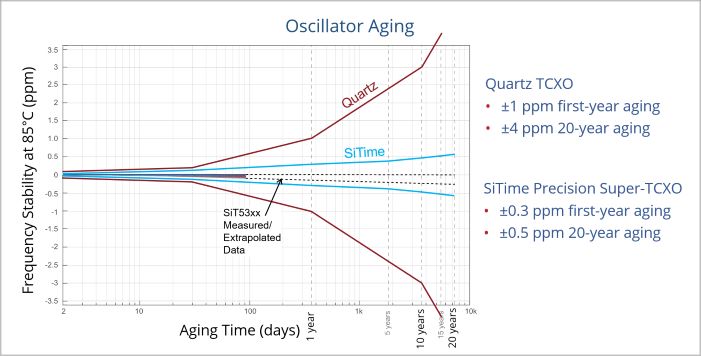

Additionally, low oscillator aging is critical to seismic sensors which are often deployed in remote locations with inconsistent satellite time reference. Elite Platform precision TCXOs age just 300 ppb during the first year of operation and 500 ppb over twenty years, which is eight times better than the rate of aging of quartz oscillators. This enables seismic sensors to maintain high accuracy and strong data integrity over long deployment periods.

Figure 4. Oscillator aging of quartz TCXOs compared to MEMS Super-TCXOs

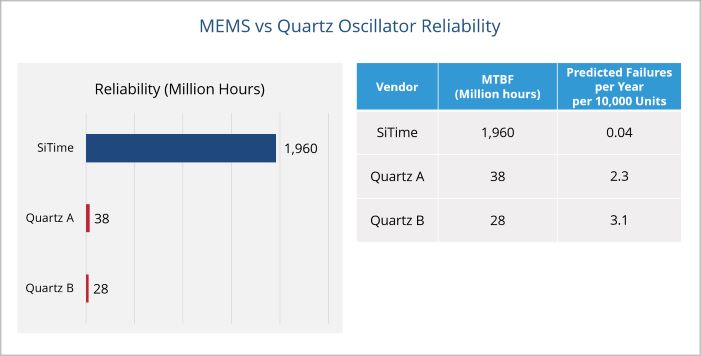

Seismic sensors need to operate reliably in a variety of harsh environments and difficult conditions. MEMS technology is inherently reliable. The MTBF (mean time between failures) of SiTime TCXOs is 1,960 million hours, which is about 50 times better than quartz devices. This translates to 50 times fewer failures per ten thousand units than quartz oscillators.

Figure 5. Mean time between failures (MTBF) of SiTime MEMS and quartz oscillators

When designing a seismic sensor system, consider MEMS Super-TCXOs. These TCXOs offer critical stability over temperature slope for accurate time stamping along with ultra-low aging to ensure timing within the system will remain accurate for decades. It is important to select timing solutions that offer the highest reliability and perform under the harshest environments.

..............................................................................

Related resources:

DualMEMS and TurboCompensation Temperature Sensing Technology

Timing Solutions for Industrial Applications

..............................................................................

Thanks to Robin Ash for her contribution to this article.