Why Precision Timing Holds the High Ground Over Quartz (Part 2 of 2, Programmability)

The latest innovations from engineering mean you can now achieve performance and bandwidth never before possible. Driven by AI, electronic systems are handling increasing volumes of data through deeper levels of integration, miniaturization and interconnection, reaching new levels of achievement in datacenter infrastructure and beyond.

Precision timing is necessary for synchronizing the data transmission through these high-bandwidth, high-performance and distributed computing environments. Welcome to part 2 of our Precision Timing series, where you will discover why precision timing holds the high ground over quartz-crystal products, upleveling your timing technology with programmable flexibility.

Programmability: The Game-Changer in Timing Solutions

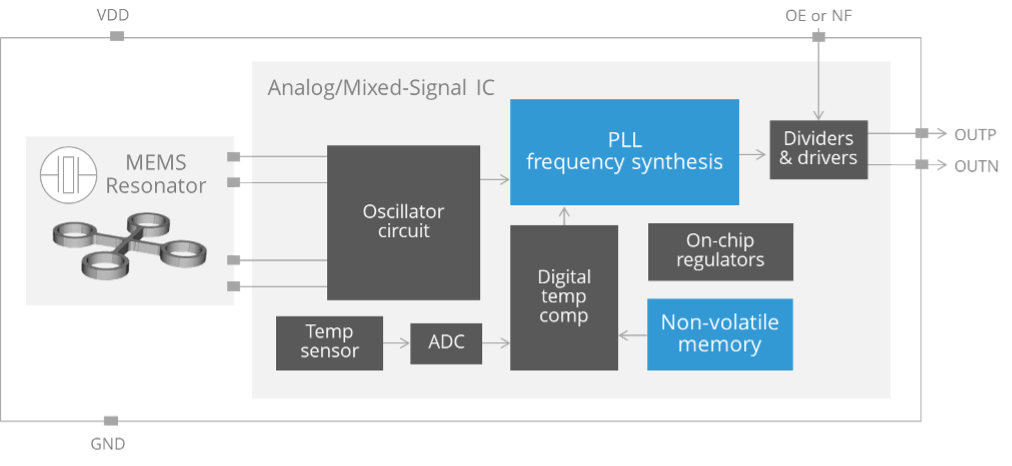

SiTime MEMS-based, programmable architecture brings new levels of flexibility and precision, distinguishing it from the legacy timing market. In fact, these characteristics are a big part of the definition of a newer precision timing category. Precision timing solutions combine a MEMS resonator with an analog/mixed-signal oscillator IC, which are brought together using advanced systems integration and packaging technologies. A phase-locked loop (PLL), dividers, non-volatile memory and other proprietary features deliver this programmability.

SiTime oscillators can be programmed for any output frequency, output format, and supply voltage within a wide range, offering unparalleled design optimization opportunities. This programmable architecture ensures that SiTime oscillators are readily available at almost any frequency, drastically reducing time associated with producing traditional quartz oscillators with custom frequencies. SiTime oscillators are batch produced, stored in inventory and then factory programmed at final test to the customers’ exact specification.

In contrast quartz-based devices rarely offer programmable features. The frequency of a quartz crystal or oscillator is determined by its size and shape. This is achieved by accurately cutting, shaping and sizing a thin piece of quartz to create a specific desired output frequency. The physical size and thickness of a piece of quartz crystal must be tightly controlled since it affects the final fundamental resonance. Once cut and shaped, the quartz crystal cannot operate at any other fundamental frequency.

Programmability allows a single SiTime oscillator to replace multiple quartz oscillator SKUs, simplifying design processes and inventory management. Such versatility enables on-the-fly adjustments to meet various application requirements. For example, if design specifications change, requiring a different frequency or voltage, a SiTime oscillator can be programmed for the new specification. This eliminates the need for requalification, further streamlining the design, qualification and manufacturing process. Beyond the supply chain benefits, the programmable architecture of SiTime precision timing devices can help optimize your system’s performance and size.

SiTime oscillators are architected for programmability.

SiTime oscillators are architected for programmability.

Higher Performance: Optimizing the System Efficiency and Precision

SiTime MEMS-based oscillators offer programmable features to enhance system performance. Frequency customization allows designers to fine-tune performance by selecting the optimal output frequency. The SiTime portfolio includes a couple hundred base products that yield millions of part numbers (SKUs). Within the portfolio, the output frequency ranges from 1 Hz to 920 MHz, which can be programmed with high precision out to six decimal places of accuracy. The frequency can also be pulled up to parts per million (ppm) to support integration into control loops. Dynamic frequency control through in-system programmable (ISP) oscillators enables performance boosts via overclocking or power savings by reducing frequency during low-load conditions. Digital interfaces for programming the frequency, such as I2C, eliminate noise from sensitive analog inputs, allowing precise control.

Additionally, FlexEdge™— a unique programmable feature—reduces electromagnetic interference (EMI) by adjusting clock waveform rise and fall times, minimizing high harmonic power without affecting short-term jitter.

Smaller Area: Reduces System Size

MEMS-based timing products are smaller by nature. The programmable timing platform further reduces footprints since it can reduce component count.

Transforming the Timing Market

It’s time to move from traditional timing solutions and up-level your game to next-generation precision timing that can meet the complexities of AI, cloud, and other advanced technologies. With resilience, precision, and programmability, MEMS timing represents a paradigm shift with programmable precision. As the electronics industry continues to reach higher bars, new levels of performance, integration, and reliability are needed, establishing MEMS-based precision timing as the preferred choice for future-focused electronic applications.

For more information, check out part 1 of this Precision Timing series at Why Precision Timing Holds the High Ground Over Quartz: Hardware (Part 1 of 2)