How Precision Timing Drives Factory Automation Efficiency and Reliability

Automotive assembly line robotics must install parts within a millimeter of precision—even minor timing errors can lead to misalignments, defects, costly rework and production delays. Robots in factory settings can endure shock, vibration and temperature fluctuations which can impact timing. Traditionally, factory automation has relied on Programmable Logic Controllers (PLCs) and industrial control systems with flexible (or “loose”) timing, enabling sequential processes like tire assembly and component integration without strict synchronization. This approach was sufficient in the past.

Today’s increased automation demands more precise synchronization across systems, boosting efficiency. Manufacturers can now achieve faster production speeds with fewer errors, leading to reduced operational costs through energy and material savings. Smart automation improves product quality by enabling real-time defect detection, reducing waste and enhancing customer satisfaction. Unreliable timing not only undermines the efficiency gains but also quality control, making defect tracing difficult and driving up costs.

This article explores key trends in factory automation and robotics, focusing on precision timing solutions to transform manufacturing across industries.

Trends Driving Factory Automation and Robotics

These emerging strategies are trending, defining the future of factory automation and robotics:

- Time-Sensitive Networking and Precision-Time Protocol (IEEE 1588) Enhances Coordination Between Machines and Systems

Oscillators are typically the preferred solution for timing in robotic systems, especially in fixed robotic arms where accurate timekeeping is crucial for precise movement. Time-Sensitive Networking (TSN) and Precision Time Protocol (PTP) provide tighter synchronization, improving coordination across the factory floor.

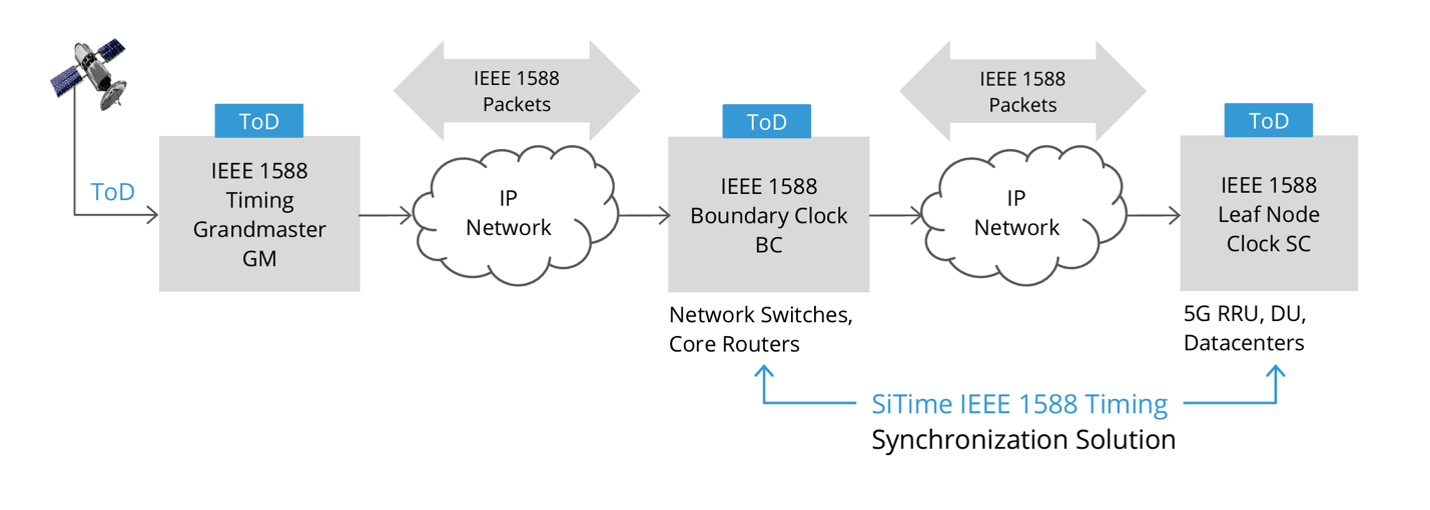

TSN, developed by the IEEE 802.1 working group, enhances Ethernet with time synchronization and traffic prioritization for low-latency, deterministic networking in industrial applications. PTP, standardized as IEEE 1588, synchronizes clocks across networks with sub-microsecond accuracy, ensuring coordinated system operation and improved efficiency. Together, they optimize workflows and minimize delays in industrial environments.

Even for teams with domain expertise, designing a custom PTP solution from scratch is a complex and time-consuming process. SiTime’s IEEE 1588 plug-and-play timing synchronization solution combines SiTime’s MEMS precision timing with a complete IEEE 1588 software to deliver an environmentally resilient, accurate timing synchronization solution.

- Smart Machine Vision and AI for Defect Detection

AI-powered image processing enables real-time defect detection, reducing faulty products. Multi-spectral and 3D cameras help identify surface and structural defects for a more thorough inspection. Automated defect sorting systems streamline quality assurance, improving efficiency and consistency.

Precision timing devices synchronize high-speed cameras and processing systems, ensuring accurate image capture and analysis. This minimizes latency, enhances inspection accuracy and optimizes automated sorting for improved manufacturing efficiency.

- Industrial IoT (IIoT) for Real-Time Monitoring

Smart sensors track key parameters like temperature, pressure, and vibration, helping to prevent equipment failures by detecting irregularities early. Edge computing processes data instantly on-site, enabling quick decision-making. Cloud integration allows remote monitoring and provides predictive analytics, enabling proactive maintenance and performance optimization.

Precision timing ensures accurate synchronization of IIoT sensors, edge computing and cloud systems, enabling real-time data processing and accurate anomaly detection, enhancing predictive analytics and system reliability.

- Robotics and Automation for Speed and Accuracy

AI-enhanced robotic arms improve precision in assembly, welding, and inspection, ensuring higher quality and consistency. Automated Guided Vehicles (AGVs) optimize material transport and minimize errors, improving logistics efficiency. Collaborative robots (cobots) work safely alongside humans, boosting productivity and enabling seamless human-machine collaboration.

Precise timing devices synchronize robotic arms, AGVs and cobots, ensuring seamless coordination, minimizing latency, and optimizing task execution for improved safety and efficiency in industrial automation.

On the Factory Floor MEMS Precision Timing Beats Quartz

Silicon MEMS devices provide an advantage in timing to address automation’s emerging trends across the board. Quartz devices are typically larger than their MEMS silicon counterparts, making them more susceptible to mechanical g-forces and increasing sensitivity to shock and vibration typical in factories. The differences in material strength, mass and construction mean that quartz timing devices are more likely to crack or break under shock compared to MEMS silicon devices.

In addition, quartz-based timing devices are more sensitive to temperature fluctuations, which can lead to greater frequency drift over a range of temperatures. While quartz can be temperature-compensated to some degree, it still tends to exhibit a higher level of sensitivity to temperature changes compared to MEMS devices. MEMS silicon has a more stable coefficient of thermal expansion than quartz, making them more stable across a wider temperature range. This is especially important in industrial applications where temperature variations can be significant.

Key timing device features to consider in factory automation and robotics:

- Temperature stability: Ensures consistent performance in varying conditions.

- Shock and vibration resistance: Protects against mechanical stresses.

- PPM accuracy and stability: Enables long-term reliability.

Driving the Future of Factory Automation and Robotics with Precision Timing

To thrive in an increasingly digital industrial landscape, manufacturers must embrace precision timing, AI-driven automation and real-time monitoring. As automation advances, leveraging MEMS-based timing solutions and integrating cutting-edge technologies will be crucial in ensuring efficiency, reliability and competitiveness. As the only technology company solely dedicated to precision timing, SiTime is a leader in advanced timing solutions for the next generation of automated and robotic systems shaping the future of manufacturing.

SiTime Brings Precision Timing to Factory Automation

For information on SiTime applications and products for factory automation and robotics, please see: