SiTime Oscillators Replace Discontinued Murata Resonators, While Upgrading System

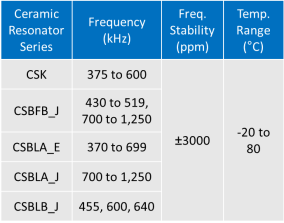

In March of 2018, Murata will discontinue three ceramic resonator series: CSBLA_J, CSBFB_J, and CSBLB_J. These resonators join the CSK and CSBLA_E series on Murata’s list of discontinued kHz devices. According to the company’s website, Murata has no replacement parts for these resonators, causing supply chain disruption for many customers.

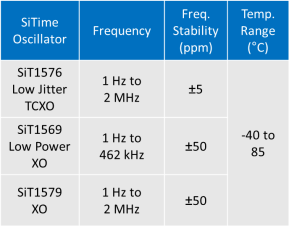

There’s good news. Low-frequency SiT1576, SiT1579, and SiT1569 oscillators from SiTime provide a functional alternative to the Murata ceramic resonators. Only SiTime offers this range of kHz solutions, saving OEMs and ODMs from facing difficult design decisions.

![]()

Replace Murata and Upgrade – In One Move

End-of-life products with no replacement are a sign of aging or obsolete technology. SiTime solutions, based on revolutionary MEMS and analog technology, provide both a replacement and an improvement. SiTime kHz solutions offer far better stability (±5 ppm compared to ±3000 ppm), in addition to the following benefits:

- Better quality and reliability

- Immune to shock and vibration

- Lowest sensitivity to EMI

- 1.2 mm2 package, reducing PCB area

- Drives multiple loads to replace multiple resonators, reducing BOM and PCB area

SiTime SiT1576, SiT1579, and SiT1569 oscillators are easy to design-in and don’t require external components such as load or bypass capacitors. Because they are a completely integrated timing solution, these “plug-and-play” devices eliminate the hassles of matching a resonator to the oscillator circuit. Parameters such as crystal motional impedance, resonant mode, drive level, oscillator negative resistance, and load capacitance are no longer a consideration. Since matching errors are eradicated, start-up is guaranteed.

Guaranteed Supply, Ultra-Short Lead Times

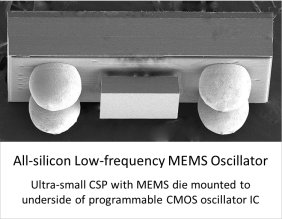

While no one likes to deal with obsolete parts, there can be a significant upside to using new technology. MEMS technology is inherently suited for smaller size, better performance, and higher robustness. In addition, SiTime MEMS solutions provide substantial supply chain benefits and flexibility, with a wide range of frequencies as low as 1 Hz. This flexibility, coupled with very fast lead times, is enabled by MEMS technology and the programmable architecture employed in SiTime products.

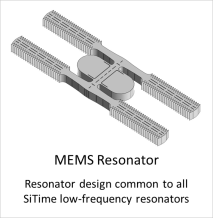

All of SiTime kHz oscillators are based on the same silicon MEMS resonator design (shown above), making mass production extremely scalable. The MEMS resonator die is mounted to a programmable oscillator IC. Output frequency is configured with a phase-locked loop (PLL) and stored in one-time programmable (OTP) memory – both located in the oscillator IC. This arrangement allows for a large variety of configuration parameters and features. These all-silicon ingredients enable a highly efficient and sustainable manufacturing model.

In contrast, the frequency of quartz resonators is attained through the physical size and shape of the quartz crystal. Because various crystal cuts are required to produce different frequencies, manufacturing and support for a wide range of frequencies are difficult for quartz companies to manage, especially in lower frequencies.

Supply chain benefits are built into SiTime’s future-focused timing technology. MEMS oscillators have been rapidly replacing quartz technology since they entered mass production 10 years ago. To learn more about the advantages of MEMS oscillators, read our white paper on The Top Eight Reasons to Use an Oscillator instead of a Crystal Resonator.