Maximize efficiency and lower qualification costs

In our last blog, we highlighted the total cost of ownership as it relates to oscillator performance and features. However, some of the largest cost savings come from the business and supply chain benefits of programmable MEMS oscillators. Qualifying components is one cost to consider, since it can amount to tens of thousands of dollars, for a derivative product using a similar component and hundreds of thousands of dollars for a brand-new component.

Component qualification is the process of testing electronic parts to ensure they meet specific requirements before they are integrated into a larger system or product. It’s an important step in the development of electronic products since parts that fail to meet the necessary standards can compromise the safety, reliability, and functionality of the entire system. But what if end-product manufacturers could skip this costly and time-consuming process? In addition to saving resources, how much would be gained by getting to market faster?

One product family, one qualification

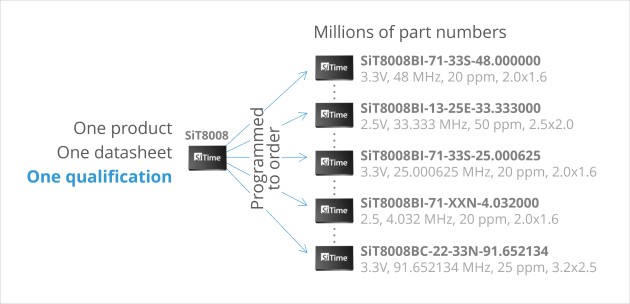

SiTime silicon MEMS timing products can enable customers to take a pass on component qualification, while lowering risks at the same time. This is because qualifying one SiTime part is like qualifying thousands or millions of SiTime parts. Our products are built on a programmable architecture and are programmed to order, enabling them to be configured to any frequency, any supply voltage, any stability, and any package within a huge range. Each product can generate thousands or even millions of part numbers.

SiTime products have a programmable architecture, enabling them to be configured to any frequency, any supply voltage, any stability, and any package within a huge range – generating thousands or even millions of part numbers.

Let’s say a customer has qualified a SiTime SiT8008 oscillator at a particular output frequency, but a new board design requires a different frequency. Or a customer is planning to design three or four products using similar oscillators but with different clock specifications. Since the SiT8008/SiT8009 oscillators can be programmed to a vast range of specifications, the existing qualification data can be extended to SiT8008/SiT8009 parts that have different frequencies (any frequency from 1 to 137 MHz), different supply voltages (any voltage from 1.62V to 3.63V), different frequency stabilities, and even different packages.

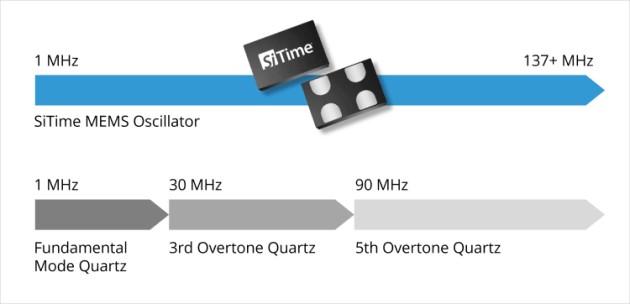

Compared to crystal quartz products that offer only select frequencies within a narrow frequency range, a SiTime product family – which shares a common set of silicon die and the same qualification data – can offer any frequency within a large range.

In contrast, quartz-based products can’t offer this type of flexibility. The frequency of quartz crystals is dependent on the thickness of the quartz blank. Each quartz blank is cut for a specific frequency, which means each quartz part requires new qualification data. And because most quartz products are not programmable, they also have fewer stability and voltage options. What’s more, if the frequency is less than 30 or 40 MHz in one design and higher in another design, the quartz device usually changes from a fundamental mode crystal quartz oscillator to a third overtone or fifth overtone crystal quartz product – a different oscillator technology and design altogether.

The output frequency of a SiTime oscillator family, which shares a common set of silicon die (no quartz crystals are used), can span a very large range and with extremely fine resolution. For example, our single-ended oscillators typically range from 1 MHz to 137 MHz, our dual-ended (differential) oscillators range from 1 MHz to 725 MHz, and our Super-TCXOs range from 1 MHz to 220 MHz – with up to six decimals of accuracy.

Reduce qualification efforts

What does component-level qualification entail? Qualifying parts for end-use conditions can consume substantial time and resources. It typically involves several stages, including design verification, reliability testing, and production testing. First, the product and quality documentation must be reviewed. Then the product must go through long-term reliability testing. Production testing is the final stage and involves testing a large number of parts to ensure consistency and make certain the parts meet specifications in a production environment.

SiTime is a Six Sigma company. We produce products that have extremely consistent high quality with failure rates of less than 1 DPPM. This is among the best in the semiconductor industry and is about 50 times better than most quartz-based components. High quality and reliability bring peace of mind along with cost savings. But skipping the reliability and production test steps because the base part is already qualified, brings considerable benefits since these stages require significant time. For example, during reliability testing the product may be placed in an oven for accelerated aging and over the course of months it is pulled out to take readings and analyze, and then it is put back in the oven. Sometimes there are failures and sometimes there are false negatives – causing the process to start over. Why go through this process if you can use an already-qualified timing product that meets a wide range of design needs?

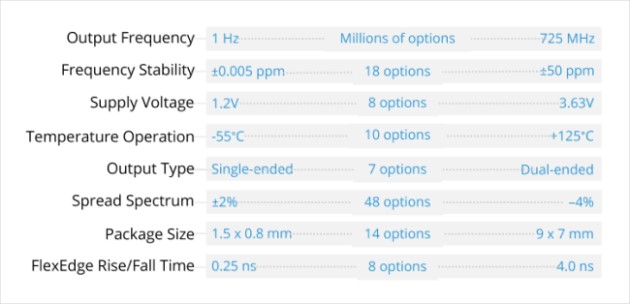

SiTime has a vast range of product specifications available across several oscillator categories, creating the largest portfolio of oscillator part numbers offered by any single supplier.

The huge range of specifications available from SiTime products lowers component qualification cost. But it can save in other ways. For example, what if a design change is made that requires a timing product that your suppliers don’t carry. Not all oscillator vendors offer a large range of products. If a new timing supplier needs to be qualified, the costs can be in the hundreds of thousands of dollars. SiTime can mitigate this cost hazard. We offer the largest range of oscillator part numbers. Most of our oscillators are pin-compatible with quartz devices and can be drop-in replacements for quartz in existing designs without any board changes.

Another benefit of SiTime MEMS oscillators is the speed at which they are available. We can program oscillators to order and have them ready to ship in as fast as 48 hours.

The programmable architecture of SiTime solutions enables ultra-fast lead times. On SiTimeDirect, millions of products can be configured to your exact design needs in seconds, purchased with easy payment options, and are ready to ship in as fast as 48 hours.

Qualification is an important process in the electronics industry – needed to ensure safety, reliability, and functionality. But businesses are focused on the bottom line now more than ever, balancing where to invest time and resources. When making a design change like changing frequency, if using the right oscillator, it can be done without triggering a complete requalification effort. Why spend time qualifying parts when you can shorten time to revenue, shift resources to other areas of engineering, and focus on your next innovation?

………………………………………………………………….

Related Blogs

Do you know when to use a crystal or an oscillator? The wrong answer can cost you.

Top supply chain benefits of programmable timing

Related Resources

Timing Essentials Class: MEMS Oscillators Fundamentals

………………………………………………………………….

Thanks to Eric Garlepp and Robin Ash to their contributions to this article.