MEMS Timing for Ultrasonic Lens Cleaning

| Devices | Key Features | Key Values |

|---|---|---|

|

TCXO

SiT5008 10 to 60 MHz

|

|

|

|

XO

10 standard frequencies:

8, 10, 12, 16, 24, 25, 27, 32, 48, 50 MHz |

|

|

As automotive and industrial sensor systems become more widely used and relied upon, it is important they operate dependably without obstruction. Ultrasonic lens cleaning (ULC) uses precisely controlled vibrations to remove contaminants that may block camera-based sensors. SiTime MEMS timing provides the perfect small-size, low-power, vibration-resistant solution for reliable clocking in ULC.

Less power and sizeSmall form factor Low power consumption |

Accurate and robustExcellent stability over temperature Resilient to vibration |

Built to lastNo quartz reliability issues Higher quality |

Ultrasonic lens cleaning (ULC) uses precisely controlled vibrations to vibrate the lens at its resonant frequency, causing contaminants to be ejected away from the lens surface. Different vibration modes are adapted to remove water, mud, ice, and more.

Ultrasonic lens cleaning is particularly useful for automotive, industrial, robotics, surveillance and defense applications.

Texas Instruments offers two devices for ultrasonic lens cleaning system: the ULC1001 PWM modulator and the DRV2901 driver. The DRV2901 drives a piezoelectric transducer which sets the lens in motion.

The TI ultrasonic lens cleaning system requires a single 10 MHz oscillator as a clock source with a recommended ±5 ppm stability over temperature. The MEMS-based SiT5008 TCXO meets this requirement in a very small footprint (2.5 x 2.0 mm). If ultra low power and a smaller form footprint (1.6 x 1.2 mm) is desired, the ±25 ppm SiT1625 oscillator can be used.

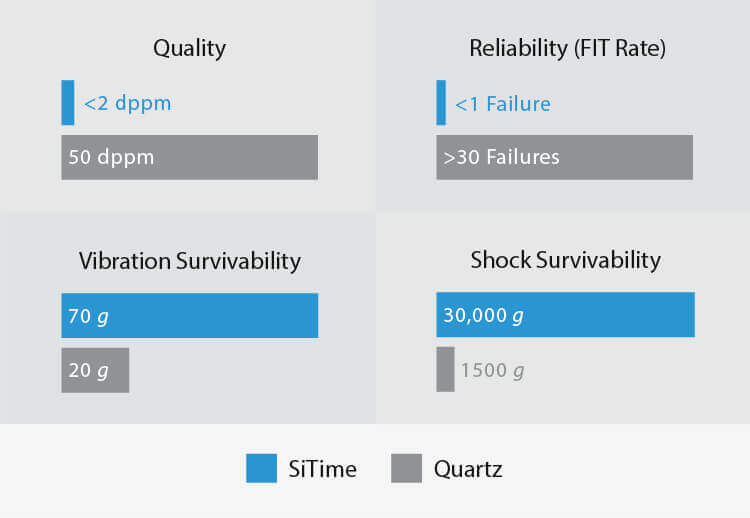

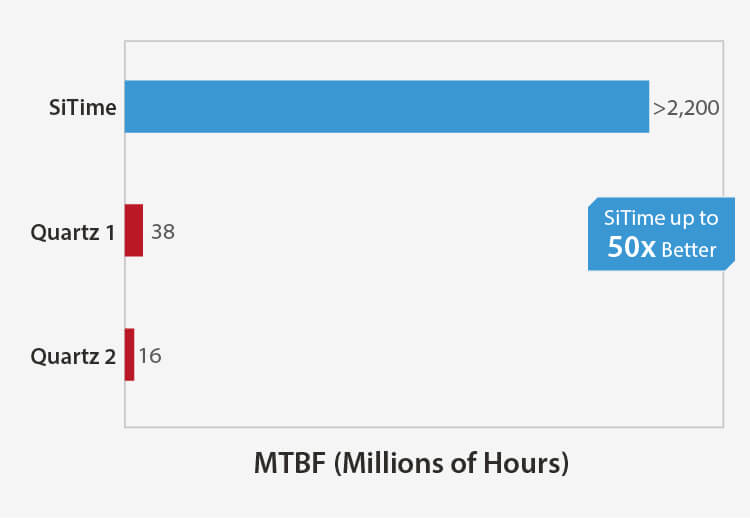

Due to their construction, silicon MEMS oscillators are 30 times more resilient to shock and vibration than quartz-based devices — an important factor in a vibrating environment such as ultrasonic lens cleaning.

MEMS resonators are hermetically sealed and therefore insensitive to contaminants, which can be present in industrial and defense environments.

| Devices | Key Features | Key Values |

|---|---|---|

|

TCXO

SiT5008 10 to 60 MHz

|

|

|

|

XO

10 standard frequencies:

8, 10, 12, 16, 24, 25, 27, 32, 48, 50 MHz |

|

|

SiTime devices offer the following advantages over traditional quartz-based oscillators:

Better Quality, More Robust |

Millions of Configurations |

|---|---|

|

Image

|

Image

|